For years now, 13 years in fact, we’ve had our old faithful ARB Air Compressor fitted under the bonnet of the TJ. It was one of the very first modifications we undertook, and while the team at ARB did a bit of a hatchet job installing it, it has served us well in quite horrible conditions for all these years.

However the rate of tyre inflation has always been fairly average and yes while the main job for this style compressor is to operate lockers, rate of tyre inflation is also important.

On our most recent return journey from Fraser Island, adding even a few PSI to the tyres after coming off the barge on the tarmac, in the heat of day, seemed to take forever.

This seemed to be the catalyst to start looking around to see what was out there.

The obvious choice was the now remodelled ARB air compressor although the less than 100% duty cycle was a bit of a let down on this model.

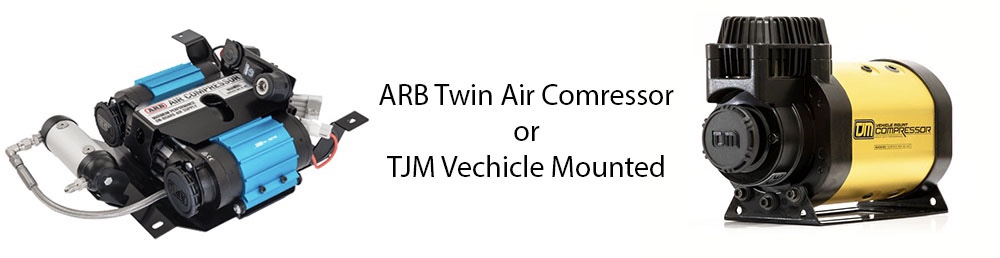

The cream of the crop in the air compressor game at the moment is the ARB twin air compressor. With 100% duty cycle and an unbeatable inflation rate, it’s by far and away the class leader.

This is where the compromise situation kicks in as the ARB twin air compressor is huge and has no place in a small TJ Wrangler. There is literally no place to put it. It simply won’t fit where the old compressor came from and while it could go in the cabin, it would take up space required for other needs. The other main issue of course is price which is a consideration.

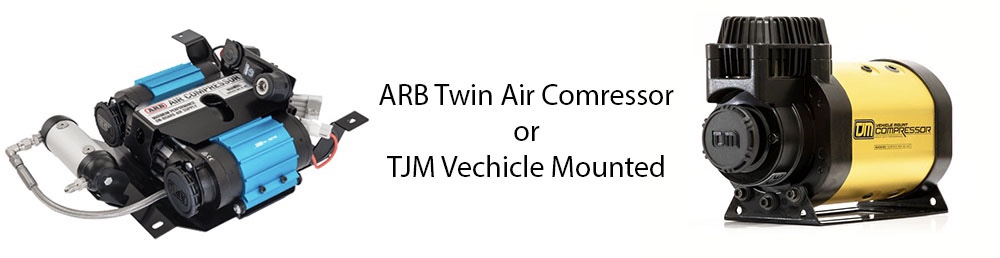

The only other option on the market at the time, that can be easily vehicle mounted and has 100% duty cycle is the TJM Vehicle Mounted air compressor.

It’s larger than our old ARB compressor so unfortunately it also won’t fit where the old one was, but no so big that we couldn’t find a space inside the cabin for it.

The end result sees the air compressor mounted in the space behind the roll bar in the rear right hard corner.